Product prototyping is not just a trending buzzword, but a key component of the product development process. The idea is to help you fast-track the prototyping process and ensure that your idea comes to fruition in the fastest possible time.

So, it is not just some checkbox to be checked, but a process in which you need to be involved and work closely with the chosen prototyping service.

Here we will present some of the most important hallmarks of a great prototype. A sort of a template that can be applied to every prototype, regardless of the industry and specific features.

Understand your requirements

Every product has specific requirements and problems that need to be addressed. There is no such thing as one bill to fit them all. But the problems will even increase if you are not intimately familiar with all aspects of your prototype.

The idea is to be clear with yourself on what you want to achieve, which features matter to you most, in which areas you can make a compromise, and your end goals.

Failing to do so will result only with you spending a ton of money on nothing!

Choose your prototype provider wisely

Nowadays, there is an abundance of companies that offer prototyping services. However, not all are as amazing as they say.

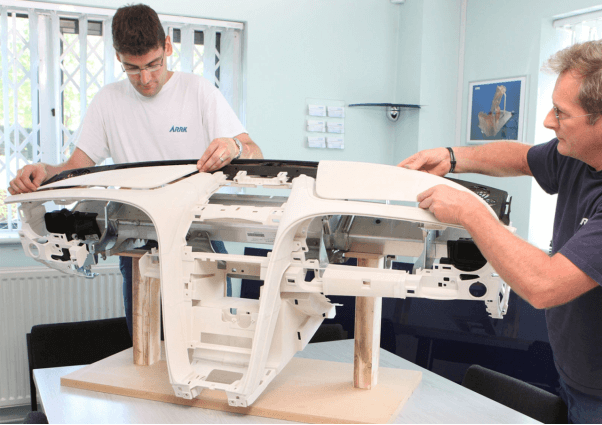

The best ones add value to the process, and by that, they increase your chances of creating a successful prototype.

The best ones don’t just run their machines and software, but also offer access to the know-how of their engineers and designers. All with one goal, to bring your prototype to life.

The best ones can be identified through their portfolio, the technology they use, as well as the expertise of their people.

Understand the properties of the material used in your prototype

Not understanding the properties of the materials used in the prototype is a common mistake made by a lot of folks that try to bring a physical product to life.

For instance, two similar materials can share 99% of their properties such as strength, hardness, and resistance. But that 1% in flexibility can sometimes make all the difference in the world for your prototype.

Again, it is about doing your homework and understanding the peculiarities of the materials you plan to use for your prototype.

That way you can make and test several iterations of your prototype before making the final selection for the material you will use.

Define clear goals for each iteration

Again, we are repeating the original mantra, but this time with an accent on the iteration process.

In most cases, several iterations are to be expected, if not more. There can be iterations related to the material of the prototype (something that we’ve touched a moment ago), the design of the prototype, some of its features, or something else.

What matters is to plan ahead as much as possible, make sure that you take note of the outcome of every iteration, and analyze it. You need to understand what each iteration brings to the table, how it fits overall, and how it compares to the iteration before or after.

Escape tunnel vision

It’s easy to lose yourself in the details and miss out on the big picture. That can happen not only to one person but an entire team.

The fix to that is to get some fresh eyes on it, another perspective, different than yours or one of your team members.

Allow other people to interact with the prototype or even some of its iterations, and simply observe them. Take note of their reactions, what they like, what they dislike, and how they interact with it in general.